Dust Collecting & Drying

Dust Collectors, Pulse Jet Type and High Efficiency Cyclones

Pulse Jet Dust Collectors

This range of Pulse Jet Dust Collectors is designed to filter particulate using conventional felted media or pleated type cartridges in any industry which requires removal of particulate or fumes.

These filters are accepted as the standard in this industry, with collection efficiencies in excess of 99.9%.

Temperatures of up to 260 deg C are standrad with special filters and construction up to 760 deg C. Design incorporates top inlet and impact plate for achieving low operating pressure drop. CAS Enterprises can design a system to meet requirements, or consult for existing systems and testing.

Construction

- Stainless steel or carbon steel are standard in various sizes of round or square.

- Insulation is installed if process air is humid.

- Easy cleaning is achieved by quick release clamp on man access doors.

Optional

- Explosion vents

- Explosion detection or prevention

- Dust emission sensors

- Dust discharge valves - rotary or flap

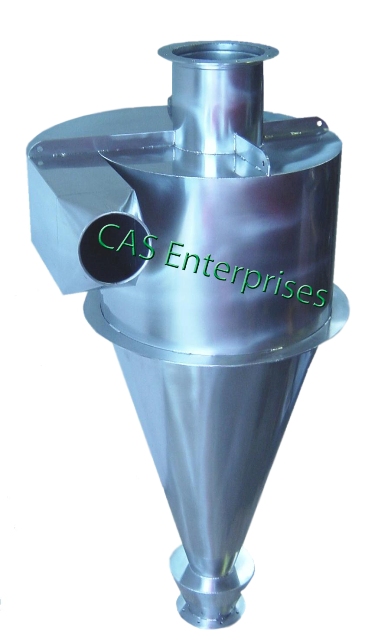

Cyclones

Cyclone collectors provide typical efficiency levels of 90% removal at 10 um – with a particle specific density of 1.0. This section is currently being updated

Ventrui Scrubbers

"Our Robson Scrubber"

A highly efficient Venturi type scrubber that generates very low pressure drop when processing particulates. This machine has ‘leading edge technology’ and offers superior performance levels.

Examples:

- 95% collection at 1.0 micron with a 70mm pressure drop

- 65% collection at 0.6 micron with a 70mm pressure drop

Silo Vents

This section is currently being updated.

Dryers

Fluid Bed & Spouted Bed

Where drying, agglomeration, and coating is required for food, chemical or pharmaceutical products the combination of air and vibration is ideal. This combination produces high heat transfer efficiency and gentle handling. Special distributor plates optimise fluidising. Vibratory systems are used for operating temperatures up to 200 C while a static bed is used for temperatures up to 800 C (specialised applications).

- The process air is filtered by either felted media or polyester spun wound cartridges situated above the fluid bed. This has the advantage of no product carry-over in the outgoing air. Having the filter dust collectors above the bed ensures easy cleaning and hygienic operation.

- The process air can be re-circulated. Air/air and air/water heat exchanger options are available for very high thermal efficiencies. For drying, moistures down to 0.1% are possible, depending on the product.

- The bed can be separated into zones for high temperature, tempering and cooling as required.

- It is possible to change from a drying medium to an inert gas with a closed loop system where required.

Air Swept Mills

See also Milling section. These machines are very effective in Milling and Flashing Drying of powders in the one operation.