Vibratory Equipment

Vibratory Sifting

Linear Food Grade

Linear machines are ideal for most classifying or security sifting applications. The machines can separate powders into a maximum of four fractions.

- Machines are isolated and supported by coils springs or rubber pads on a base frame or suspended.

- Linear types: LS, OLS.

Deck Sizes from 0.6 to 3.6 m2

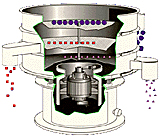

Circular Security

High throughput security sifter that features two vibratory motors, for enhanced performance.

- The machine produces above average ‘G’ forces enabling high throughputs when scalping or security sifting.

- The machine is compact in design and is also suitable for Fluid Bed Drying applications.

Models include Dairy Standard for the Nutritional and Infant Formula. This includes FDA approved gaskets and adhesives.

Motor Specifications include: Atex Zone 22 and 21 also IEC ex.

Woven Mesh options are: 304 , 316 s/s and Magnetic Stainless.

Models Nominal Deck Size Kw

CS450 450mm 0.2

CS600 600mm 0.2

CS800 800mm 0.4

CS1200 1200mm 0.9

CS1500 1500mm 1.8

Circular Tumbler

This is the most adjustable for the set up.

- This is the most flexible machine available in terms of set up, radial and tumbling motions.

- This allows fine tuning for all products, opitimising performance.

- Circular Tumblers can be used for classifying and with fine mesh sizes.

- CAS is the NZ agent for these Allgaier machines.

Circular Traditional

Standard Sweco or Kason type gyrators that feature; a single centre vibratory motor and outside discharge.

- Has up to 2 decks (or 3 fractions), and comes in diameters ranging from 600mm to 1600mm.

- Used in food processing for high throughput, scalping, security sifting or classification of powders and particles.

Ultrasonic Anti-blinding Devices

The latest technology available to eliminate, cleaning balls, and increase sifting throughput rates.

- The system can be retrofitted to existing vibratory machines.

Vibratory Conveyors

Trough

The trough conveyor is the cleanest conveyor on the market as there are no augers, slides or belts. Trough widths range from 100mm to 1200mm

Tube

The use of flexible connections at the inlet and outlet ensures an air tight system. The tube conveyor is the cleanest conveyor on the market as there are no augers, slides or belts. Tube sizes range from 25mm to 500mm - larger for special applications.

Vibratory Feeders

Electromagnetic

Five models of electromagnetic vibratory feeders are available.

- LD1, LD2, LD3, LD4 and the CAS High Stroke Model for difficult powders.

- Controllers prove 0-100% adjustment of throughput

Electromechanical

Electromechanical vibratory feeders provide an economical solution where constant throughput is required or when throughput can be adjusted during operation with the use of a special speed controller.

Pneumatic

Pneumatic vibratory feeders offer lower setup costs and can be quiet, smooth and hygienic. They are a good option for potentially explosive environments.

Batch Weigher

The CAS Vibratory Bag Filler or batch weigher is designed to weigh most powders or products with consistent performance. Accuracy is achieved by the use of a load cell and controller specifically designed for the accurate and economical batching of most products. The different Vibratory Feeder options are: Electromagnetic, Electromechanical , pneumatic and the CAS "High Stroke Feeder" for diffcult powders.

Vibratory Batching or Bag Filling

Large Bag Filler

Vibratory Tube Feeder Bag Filler.

Typically for 5, 10 Kg open mouth bags. This utilises a large Vibratory Feeder then a small Vibratory Tube Feeder to final target.

Ideal for Food applications and easy to clean.

We are not bag handling equipment suppliers, this machine is for filling to weight only.

Vibratory Motors and Flow Devices

Vibratory Motors

Click here for general features and highlights/advantages.

Autocad Drawings and Inventor 3 D Models are avaliable on request - cas@xtra.co.nz

Click here to view 2 Pole Motor specs

Click here to view 2 Pole Single Phase Motor specs

Click here to view 4 Pole Motor specs

Click here to view 6 Pole Motor specs

Click here to view 8 Pole Motor specs

Budget Bag Filler

This section is currently being updated.

Air Packer Filler

This section is currently being updated.

Vibratory Pneumatic (Linear Piston, Ball & Turbine Types)

See Cougar www.cougarindustries.com

Air Ball Instructions.pdf (380 kB)

Turbine Instructions.pdf (294 kB)

Piston Instructions.pdf (150 kB)

Truck Vibratory (12/24 volt)

See Cougar www.cougarindustries.com

Truck or DC Vibrator Instructions.pdf (589 kB)

Air Cannons

Heavy Duty for large Hoppers or Bins with difficult products.

Vibratory Tables

Electromechanical or Electromagnetic type

Vibratory tables compact powders for higher bulk density. This enhances handling characteristics and reduces product volumes for transport. We can produce a variety of sizes from 300mm square to 1200mm square.

Vibratory Destoner

This design uses air and vibration to float the product away from foreign particles such as stones, glass, metals.

Vibratory Dewatering

Vibratory dewatering machines are suitable for high flows and are used for the removal of grit or solids from process liquid or wash down liquid. The aperture ranges from 100um upwards. This machine type can also be used with hydro cyclones for sand recycling. Linear machines are adjustable to decline, horizontal or up to 4 degrees of incline to suit the application. Also Circular types being through flow or gyratory type. The additional of Ultrasonics can enable the machine to operate down to 50um.